Manufacturing delays have killed countless product launches, but Tsinghua University researchers just eliminated that nightmare scenario with holographic 3D printing that fabricates complex millimeter-scale objects in 0.6 seconds—roughly 6,000 times faster than traditional high-resolution methods that require hours.

Their Digital Incoherent Synthesis of Holographic light fields (DISH) technology flips conventional 3D printing logic entirely. Instead of rotating material containers around stationary light sources, DISH spins a high-speed periscope up to 10 times per second around motionless resin. This architectural shift enables simultaneous projection of complex three-dimensional light patterns that cure entire solid structures in single exposures, according to research published in Nature.

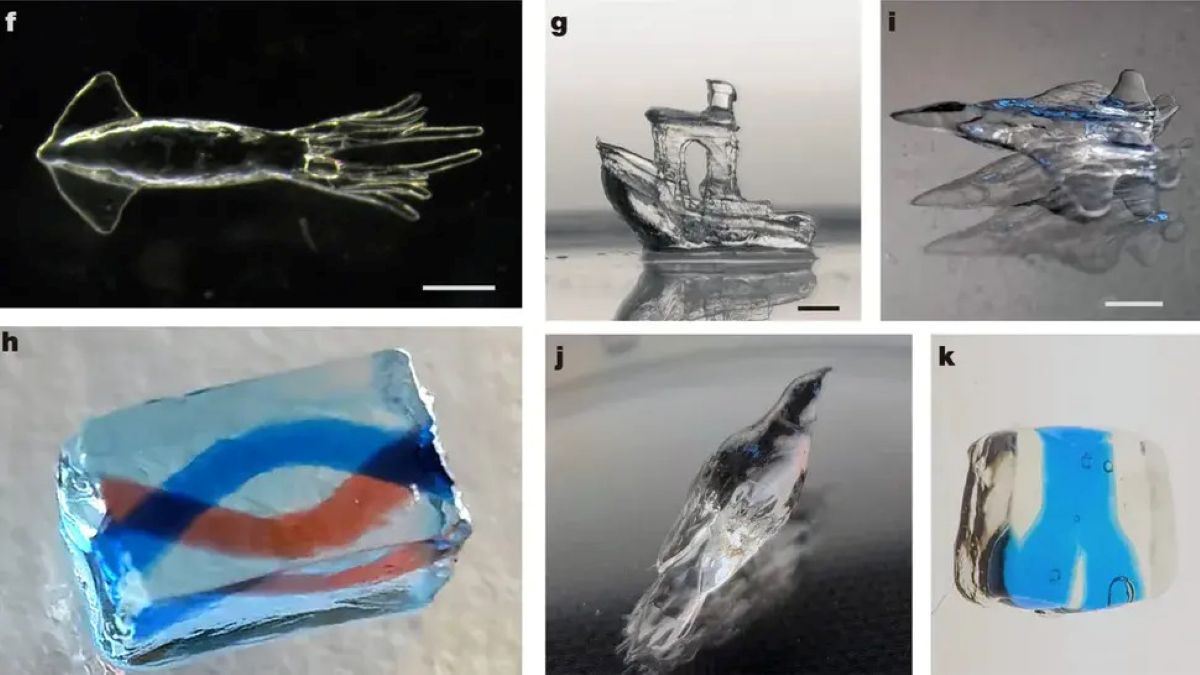

The performance specifications read like science fiction made real: 333 cubic millimeters printed per second with 12-micrometer resolution—about one-fifth the width of human hair. Even more impressive, the system maintains 19-micrometer precision across a full centimeter depth range, eliminating the shallow focus limitations that plague traditional optical manufacturing. Think Netflix streaming quality versus dial-up internet, but for industrial production.

Real-world applications target high-value manufacturing bottlenecks where speed and precision traditionally force impossible trade-offs. Photonic computing components and smartphone camera modules represent immediate targets, while the team has already demonstrated integration with fluid channels for continuous mass production. For semiconductor and photonics industries worth billions annually, rapid prototyping of micro-optical components could reshape entire development pipelines.

Commercialization timeline remains unannounced, though the five-year development period suggests serious institutional commitment beyond mere laboratory curiosities. Early adoption will likely emerge in industries with highest cost-per-failure tolerance—pharmaceutical manufacturing, aerospace micro-components, and high-end photonics where traditional printing delays cost more than experimental equipment investments.

The breakthrough treats light itself as a manufacturing medium rather than just a curing tool, fundamentally redefining additive manufacturing philosophy. Your next smartphone’s camera might contain components that didn’t exist as manufacturing possibilities just months ago.