Imagine the roar of a V10 engine. Not just any noise – this is what Zeus would hear if he stuck his head inside a volcano during an earthquake. This unique configuration sits between V8 brawn and V12 sophistication, promising a symphony of controlled chaos. Yet despite the intoxicating sound, most production V10s faced packaging nightmares, bank-account-emptying costs, and engineering complexity that would make NASA sweat.

We referenced experts at Top Gear, MotorTrend, and Car Throttle to find these engines that were magnificently potent yet as practical as swimming trunks in Antarctica. Many of these mechanical experiments proved as reliable as politicians’ promises and failed harder than a Hollywood reboot.

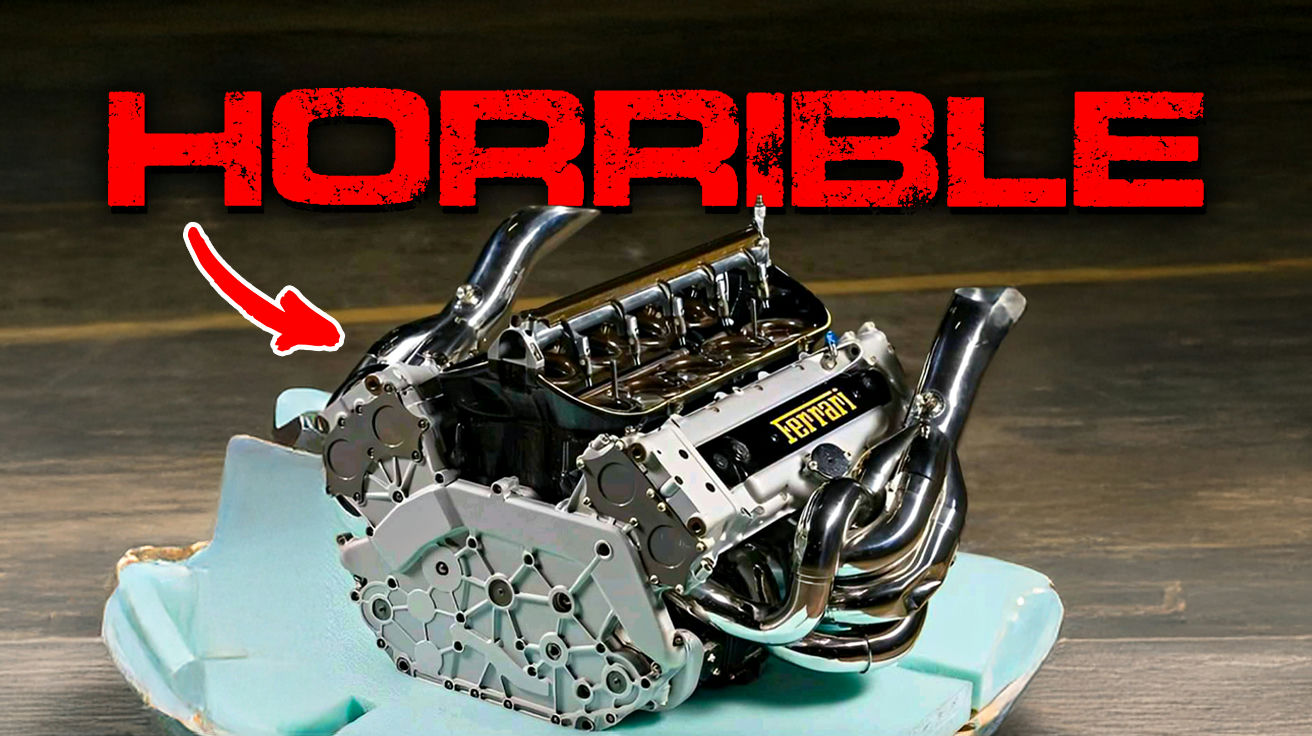

20. Peugeot F1 V10

Racing history buffs still shake their heads when discussing Peugeot’s F1 V10 program. This engine demonstrates the gap between engineering ambition and practical execution. Despite substantial development resources, the power output consistently fell short of competitive requirements in Formula One racing.

Oil leaks and cylinder misfires plagued reliability during competition, while catastrophic failures occurred with concerning frequency during race weekends. Fundamental design limitations prevented competitive performance despite ongoing development efforts, eventually causing teams to seek alternative power sources. Peugeot’s program stands as a case study in misaligned engineering objectives and practical motorsport requirements.

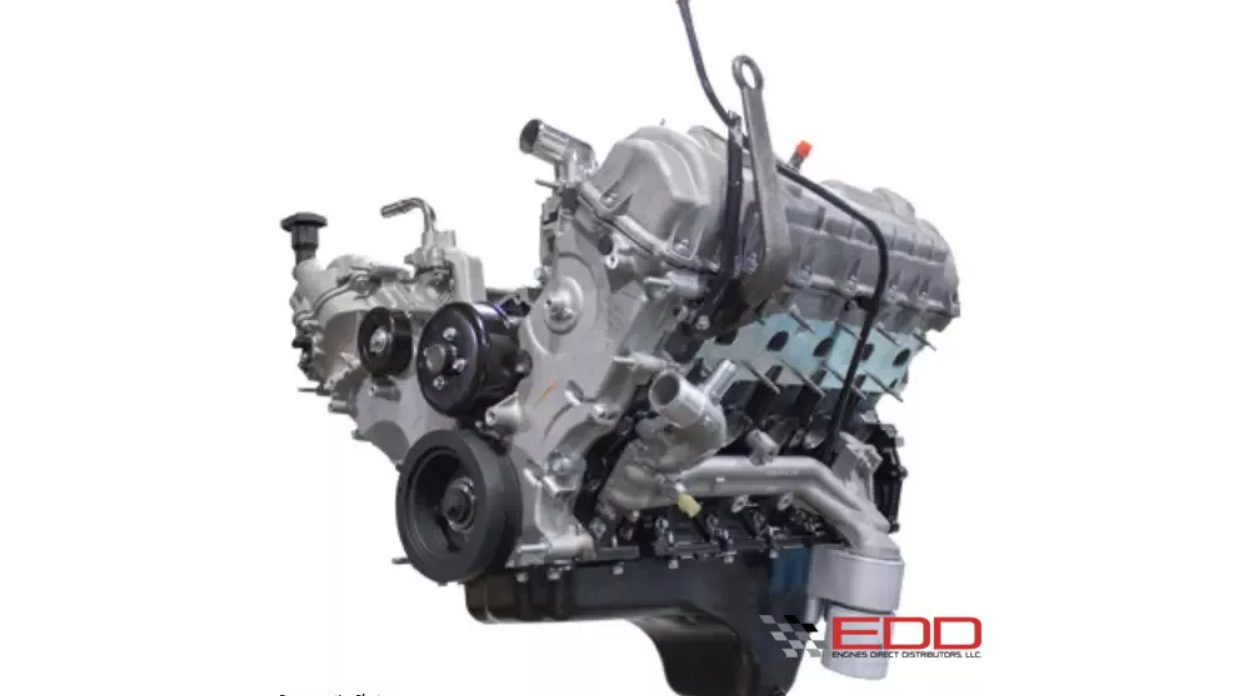

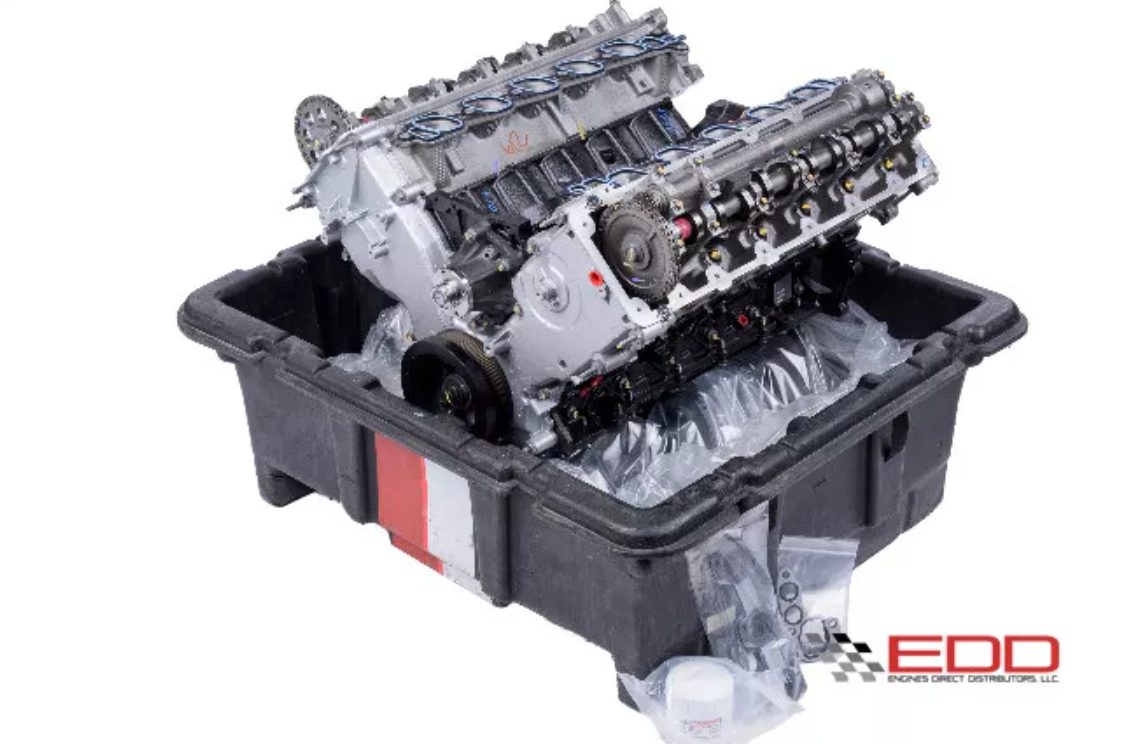

19. Ford Modular 6.8L V10

To truly comprehend the Ford Modular 6.8L V10’s design flaws requires understanding both technical specifications and user experience. The insufficient thread engagement for spark plugs creates a significant failure point, potentially leading to a sudden loss of compression when plugs eject during operation.

Exhaust manifold failures occur with notable frequency, creating distinctive ticking sounds that indicate developing problems and allow leaks affecting both performance and safety, making this one of the worst truck engines ever built.

Regular inspection might identify these issues before catastrophic failure, but cannot address the underlying design shortcomings, leading to specialized aftermarket repair techniques developed specifically to address these well-documented failure points.

18. BMW S85 V10

The relationship with BMW’s S85 V10 mirrors the classic tale of forbidden romance – irresistible yet ultimately destructive. Powering the 2005-2010 E60 M5 and E63 M6, the 500-horsepower screamer revved to 8,250 rpm with a sound that would make Ferrari engineers spit out their espresso. Upon release, car magazines fell over themselves praising its race-inspired technology – right until the rod bearings started failing with alarming frequency.

The ownership trajectory transforms from “driving god” to “financial casualty” with surprising speed. Watch for oil consumption beyond 1 quart per 1,000 miles, as this indicates impending trouble. When bearings inevitably fail, the repair bill reaches approximately $10,000, demonstrating how technical brilliance and engineering shortcomings can coexist within the same powerplant.

17. Lamborghini Gallardo 5.0L V10

Never has an engine sounded so heavenly while simultaneously draining bank accounts quite like the Lamborghini Gallardo’s 5.0L V10. This 500-horsepower aluminum masterpiece produces an iconic exhaust note but develops a concerning tendency to consume oil at an accelerated rate. Owners frequently check oil levels as part of their regular routine.

Should your cylinders develop scoring – when pistons damage cylinder walls – repair costs quickly escalate to approximately $20,000 for an engine rebuild. Blue exhaust smoke and rough idling indicate serious internal problems requiring immediate attention. Oil analysis becomes a regular ownership ritual, transforming the experience into technical monitoring rather than pure driving enjoyment while substantial financial commitment accompanies the exhilaration.

16. Dodge Ram SRT10 8.3L V10

The boardroom that approved putting a Viper engine in a pickup truck created one of automotive history’s worst pickup trucks. The 500-horsepower truck accelerates to 60 mph in under 5 seconds – impressive performance statistics but questionable utility. Fuel consumption reaches alarming levels, with single-digit MPG figures common in normal driving conditions.

The Ram SRT10 presents an identity crisis despite its truck body, offering limited towing and hauling capacity while requiring specialized maintenance. Insurance costs reflect performance potential rather than utility vehicle classification, making this vehicle excel in straight-line acceleration while sacrificing most practical truck capabilities that would justify its existence.

15. Ford 6.8L V10 (2001)

History books should mark the 2001 Ford 6.8L V10 as a monument to inefficiency because this early version established a reputation for excessive fuel consumption, with highway mileage rarely exceeding 12 mpg. The operational expenses significantly impact the total cost of ownership calculations.

Transmission performance presents another significant drawback through inconsistent shifting behavior, particularly noticeable during hill climbing or when carrying loads. Hesitation and abrupt gear changes detract from drivability, while regular maintenance might address symptoms but cannot resolve the underlying engineering limitations. These characteristics secured this engine’s position as one of Ford’s least successful powerplant offerings.

14. Volkswagen Touareg 5.0L V10 TDI

Volkswagen’s engineers took complexity to unprecedented heights with the Touareg V10 TDI. This torque monster (553-627 lb-ft) was marketed as a luxury off-roader with impressive towing capacity, yet became a technical puzzle that challenges even experienced mechanics.

The engine shows limited longevity, with fuel systems particularly prone to failure and high-pressure pumps and injectors frequently requiring replacement. Repair bills approaching $5,000 and extended wait times for parts create ongoing ownership challenges. Dashboard warning lights demand immediate attention as they typically indicate the beginning of cascading technical complications throughout the vehicle’s systems.

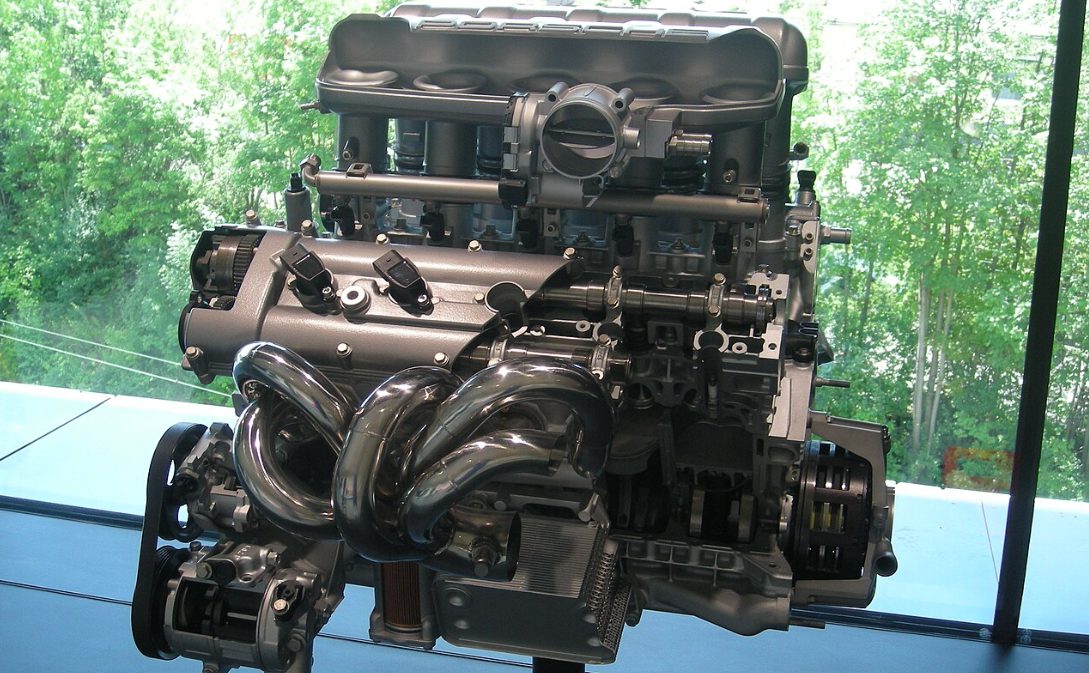

13. Porsche Carrera GT 5.7L V10

One cannot discuss mechanical perfection without mentioning the Porsche Carrera GT’s V10. With 612 horsepower and an 8,400 rpm redline, it delivers extraordinary performance figures. The distinctive exhaust note inspires emotional connection among enthusiasts, while requiring maintenance proportional to its performance capabilities.

Service schedules demand strict adherence, as deferred maintenance can result in significant mechanical failures and expensive repairs. The ceramic clutch replacement alone costs over $20,000, requiring Porsche-certified technicians for any major service work. Owning this V10 combines the pleasure of automotive perfection with the responsibility of proper maintenance and financial commitment to preservation.

12. Ford 6.8L V10 – Fuel/Exhaust (Later)

If evolution supposedly improves species, nobody informed Ford’s later 6.8L V10 models. Owners discover maintenance requirements exceeding initial expectations, while fuel economy typically ranges between 8-10 mpg, making operational costs a significant consideration in ownership.

Exhaust manifold cracks develop with notable frequency, allowing leaks that reduce performance and potentially introduce harmful gases into unintended areas. Ignition coil failures contribute to drivability issues through misfires and inconsistent performance, causing fleet operators to replace these engines with more efficient alternatives. Regular inspections might identify developing problems but cannot overcome the fundamental design shortcomings of this problematic powerplant.

11. Ford Triton V10

Engineers apparently designed the Ford Triton V10 during a particularly wild office party. Truck owners often experience a sudden “POP!” followed by a hissing sound as their spark plug launches from the cylinder head. This mechanical failure occurs because Ford designed cylinder heads with only four threads to secure spark plugs – insufficient for the pressures generated during operation.

Every trip to the gas station reminds owners of the compromises made, with fuel economy typically ranging between 8-12 mpg. Cracked exhaust manifolds leak potentially dangerous fumes despite Ford’s attempted fixes. While regular inspection might prevent some issues, ownership comes with ongoing maintenance challenges and unexpected repair costs that quickly exceed initial purchase savings.

10. Volkswagen Phaeton V10 TDI

Inside the Volkswagen Phaeton V10 TDI lies an engineering experiment with questionable real-world practicality. The complex diesel powerplant presents significant diagnostic and repair challenges even for factory-trained technicians.

Fuel system failures commonly appear after approximately 50,000 miles of operation, requiring parts with extended wait times and premium pricing. Emission control systems demand specialized knowledge for proper maintenance, representing Volkswagen’s ambitious but ultimately impractical engineering approach. Many owners eventually transitioned to more conventionally engineered luxury vehicles after experiencing the maintenance challenges firsthand.

9. Lamborghini Huracan V10 (Early)

Lamborghini’s early Huracan models present a masterclass in premature product release. Initial versions revealed development shortcomings despite the brand’s performance heritage. The dual-clutch transmission exhibited inconsistent shifting behavior, detracting from the driving experience in a vehicle category where refinement justifies premium pricing.

Temperature management proved problematic during performance driving, precisely when optimal functioning becomes most critical. Later production models received substantial improvements through cooling system modifications and transmission programming updates. Prospective buyers should prioritize 2018 or newer models to benefit from these engineering revisions that transformed the Huracan into the refined supercar it was meant to be.

8. Dodge Viper 8.0L V10

Among all production engines, the Dodge Viper’s 8.0L V10 stands supreme in its voracious appetite for premium fuel. Most owners struggle to achieve 15 mpg even under conservative driving conditions. The first-generation models offered 400 horsepower, eventually growing to 645 hp, all delivered with minimal refinement compared to European competitors.

Road trips require strategic planning around fuel stops since this engine transforms highways into a continuous search for gas stations. It demands premium fuel and synthetic oil, significantly increasing operational costs. The power delivery lacks subtlety but provides undeniable thrills, though monthly fuel expenses add considerably to the already significant cost of ownership.

7. Ford E350 6.8L V10 (2003)

Studying the 2003 Ford E350 V10 reveals how cascading failures begin with seemingly minor components. The PCV system commonly develops failures around 50,000 miles, initiating oil leaks that indicate developing problems throughout the engine system.

Powertrain issues and misfires typically follow these initial symptoms in predictable progression, making regular inspection valuable but insufficient to overcome design limitations. Fleet operators quickly discovered that initial purchase price advantages disappeared when factoring total ownership costs, leading to declining popularity in commercial applications where reliability directly impacts operational profitability.

6. Fiat F1 V10

Technical post-mortems of the Fiat F1 V10 engine provide valuable insights for engineering analysis. This Formula One development program produced power outputs significantly below competitive requirements, creating an insurmountable performance disadvantage during races.

Combustion efficiency and structural integrity proved problematic under racing conditions, preventing consistent performance even at reduced output levels. The program eventually faced cancellation after the technical gap to competitors became impossible to overcome, demonstrating the specialized nature of Formula One engine development and the challenges facing even established manufacturers in elite motorsport.

5. Lexus LFA 4.8L V10

The engineering brilliance behind the Lexus LFA’s 4.8L V10 represents the pinnacle of Japanese performance engineering. Revving beyond 9,000 rpm, it produces a distinctive sound signature specifically tuned by Yamaha’s acoustic division. Titanium valves and connecting rods enable this extraordinary performance – materials typically reserved for aerospace applications.

The initial $375,000 purchase price represented only the beginning of ownership expenses, with specialized maintenance requiring specifically certified technicians. Complex electronics and carbon fiber construction create unique service challenges, while limited production of 500 units worldwide makes parts availability increasingly difficult as vehicles age. This combination of exclusivity and maintenance demands creates both privilege and responsibility for owners.

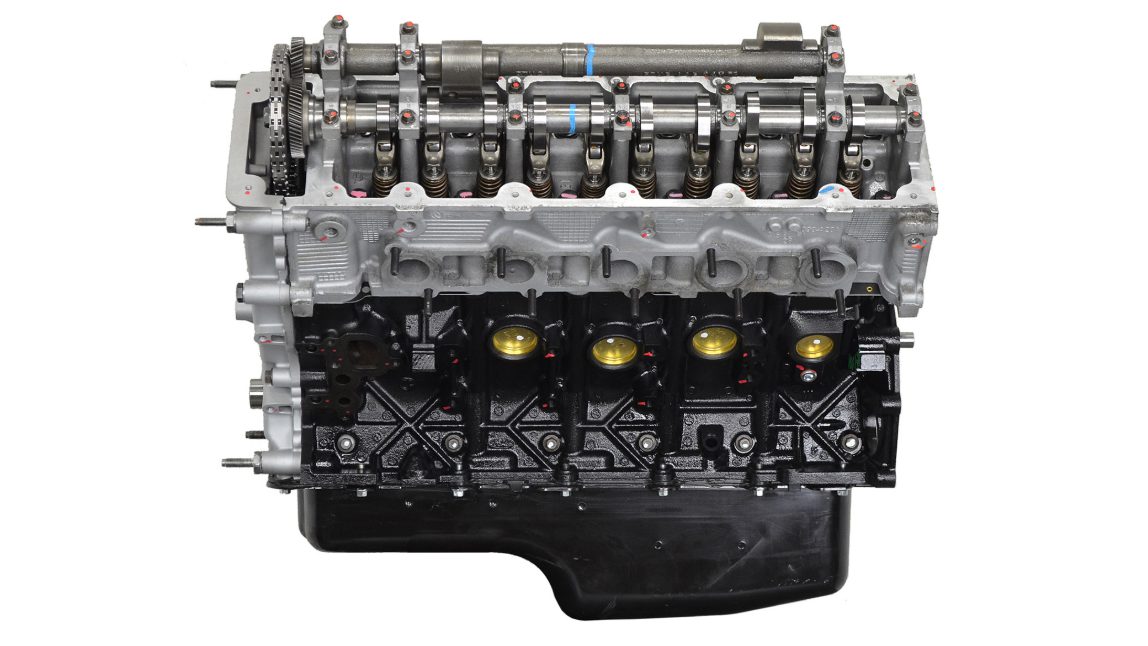

4. Ford 6.8L V10 (2017)

The 2017 Ford 6.8L V10 represents the automotive equivalent of outdated technology refusing to evolve. Cylinder misfires occur with notable frequency, creating perceptible vibration throughout the vehicle. These issues often stem from compression loss that proves challenging to diagnose even for experienced technicians.

Transmission behavior under load reveals significant development shortcomings through inconsistent shifting and unpredictable responses. Computer system problems compound these mechanical issues, requiring specialized diagnostic equipment while making Ford’s EcoBoost V6 engines look technologically advanced by comparison. Regular compression testing might identify developing problems but cannot address the fundamental design limitations of this outdated powerplant.

3. Dodge Ram 2500/3500 8.0L V10

Despite all automotive evolution, the Dodge Ram 8.0L V10 maintains remarkably high fuel consumption in an era of increasing efficiency. This engine consistently delivers single-digit MPG figures during normal operation. Highway range rarely exceeds 250 miles, necessitating frequent refueling during extended travel.

A distinctive knocking sound develops under heavy loads, indicating valve train issues that worsen over time. Towing capabilities disappoint compared to diesel alternatives, while preventative maintenance only temporarily addresses these inherent design limitations. Cummins diesel alternatives demonstrate superior efficiency, longevity, and capability in virtually every operational parameter.

2. Ford Excursion 6.8L V10

Somewhere in automotive history, a Ford executive must have challenged the team to create the most inefficient passenger vehicle possible. The vehicle delivers consistently poor fuel economy, while its substantial weight impacts acceleration performance. Full-tank driving range typically remains below 300 miles, creating practical limitations for long-distance travel.

Operating costs accumulate quickly, with fuel expenses potentially exceeding $4,000 annually with moderate use. Parts availability and maintenance requirements add to the long-term financial commitment, while the vehicle’s dimensions create practical challenges in everyday use. These characteristics create a vehicle with specific applications but significant compromises for general transportation purposes.

1. Ford 6.8L V10 (2011-2013)

Manufacturing standards apparently took an extended vacation during production of the 2011-2013 Ford 6.8L V10. Faulty spark plugs create frequent misfires, while unexpected engine stalling occurs with concerning regularity, often during critical driving situations.

Manufacturing inconsistencies affected various components throughout the engine system, causing maintenance costs to exceed typical expectations. The consistent problems across multiple production years raised legitimate questions about quality control during this period, eventually causing commercial operators to transition to alternative power sources after experiencing these reliability challenges firsthand.