These engines destroyed the reputations of America’s biggest automakers. From Ford’s spark plug-launching Triton to GM’s ill-fated diesel conversion, the damage was unprecedented. Manufacturers knew about these problems but kept selling anyway. What started as cost-cutting ended in class-action lawsuits and massive recalls. Let’s examine the fifteen engines that mechanics still talk about today.

However, if you’re in the market for a good performance car, feel free to check out our roundup of 10 high performance cars that are now steals.

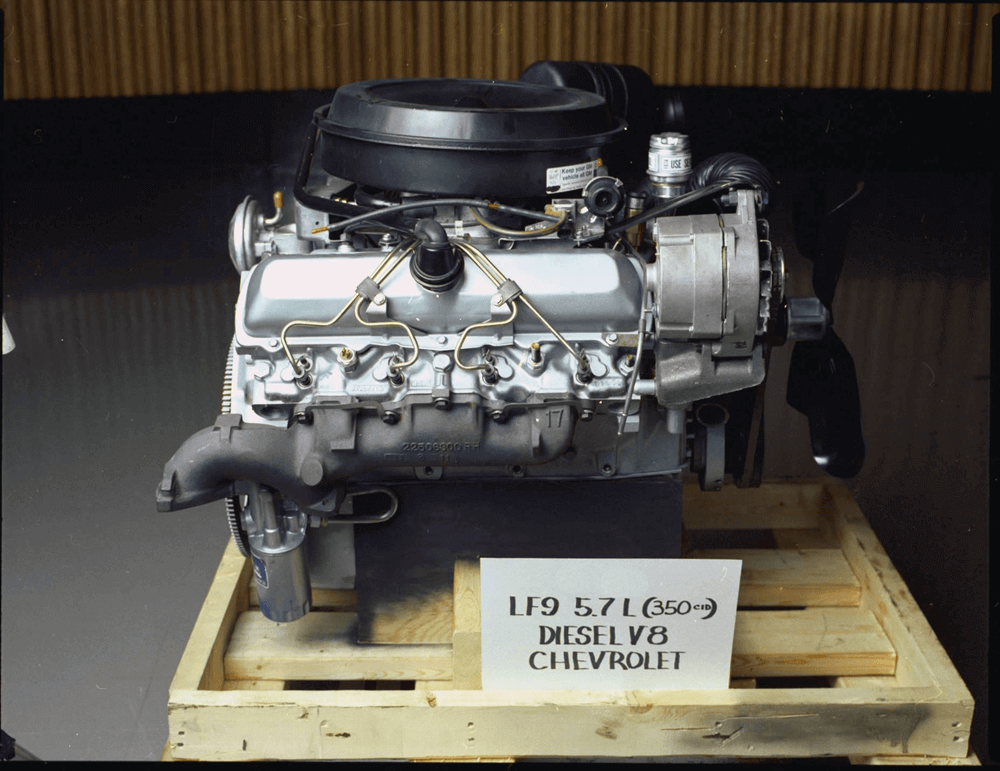

14. GM 350 Diesel V8 (Oldsmobile Diesel)

General Motors’ rushed conversion of a gasoline engine into the 350 Diesel V8 stands as one of the worst engineering decisions in automotive history. The engine catastrophically failed due to gasoline-spec head bolts that couldn’t handle diesel compression ratios, coupled with poor block strength and no water separator in the fuel system until 1981.

These design flaws, combined with inadequate dealer service training, led to widespread head gasket failures and injection system damage. Most engines self-destructed before 80,000 miles, with repair costs often exceeding $4,000. The failures were so widespread that GM faced numerous lawsuits and FTC complaints, and the 350 Diesel damaged GM’s reputation so severely that it drove many customers permanently to other brands.

13. Dodge 3.7L Magnum V6

Dodge’s 3.7L Magnum V6 exemplified everything wrong with cost-cutting engineering. This underpowered engine produced a pathetic 210 horsepower while guzzling fuel like a V8, proving particularly inadequate for truck applications. Chronic valve seat failures caused compression loss, while stuck lifters and valve lash adjusters created additional headaches. The engine’s excessive heat generation led to rapid oil breakdown, resulting in severe consumption issues that had some owners adding a quart every 1,000 miles. While proper maintenance could stretch its life to 200,000 miles, many engines required complete rebuilds well before that milestone.

12. Chevrolet 6.2L Diesel V8 (Detroit Diesel 6.2)

Chevrolet’s attempt at a diesel engine resulted in this efficiency-focused but underpowered unit. Producing an embarrassing 130 horsepower and limited to 300 ft-lbs of torque for longevity, this engine struggled to move even empty trucks. While it could achieve impressive fuel economy of 25-30 mpg when running properly, injection pump failures, harmonic damper problems, and potential crankshaft issues left owners stranded without warning.

Excessive noise and vibration made every drive unbearable, though the engine could prove reliable with proper maintenance and conservative use. Its primary redeeming quality was its fuel efficiency – when it wasn’t being overtaxed.

11. Ford 3.5L EcoBoost V6 (First Generation)

Ford’s first-generation EcoBoost proved that marketing hype couldn’t overcome poor engineering. Timing chain stretching became so common in 2010-2014 models that dealers stocked replacement parts in anticipation of failures. Direct injection led to severe carbon buildup that choked performance, while intercooler condensation issues in 2011-2012 models caused dangerous stalling.

The ignition system wore out prematurely compared to naturally aspirated engines, requiring more frequent maintenance. The 365-horsepower rating only materialized with premium fuel and perfect conditions, making it another example of ambitious marketing meeting disappointing reality.

10. Ford 2.7 L Ecoboost V6

This smaller EcoBoost continued Ford’s tradition of problematic turbocharged engines. Carbon buildup rendered the direct injection system nearly useless over time. Oil consumption reached alarming levels, forcing owners to carry spare oil on trips. The timing chain wore prematurely, creating a ticking time bomb of repair costs.

9. Toyota 3VZ-E 3.0L V6

Toyota’s typically reliable reputation took a massive hit with the problematic 3VZ-E engine. Head gasket failures occurred with shocking regularity after 100,000 miles, particularly after Toyota discontinued asbestos gaskets, costing owners thousands in repairs. The engine’s inherent cooling system design flaws led to chronic overheating issues, and its meager 150 horsepower output proved inadequate for many applications.

While some units could achieve high mileage with vigilant maintenance and careful monitoring of engine temperatures, the engine’s propensity for developing oil sludge turned many vehicles into worthless scrap. Even meticulous maintenance couldn’t guarantee against its inevitable failure.

8. Dodge 4.7 L V8

Dodge’s 4.7L V8 proved that newer doesn’t mean better. Valve seat failures occurred without warning, destroying engines in seconds. Oil sludge accumulated at an alarming rate, even with regular maintenance. The cooling system design practically guaranteed warped heads, making long-term reliability impossible.

7. Nissan 5 L Cummins V8

If anyone needed proof that prestigious partnerships can fail spectacularly, the Nissan 5L Cummins V8 provided it. The engine failed to deliver promised fuel economy while requiring expensive maintenance. Turbocharger failures became so common that owners feared highway driving. The complex design turned simple repairs into wallet-emptying ordeals.

6. Chevrolet/GMC 5-Cylinder Atlas

GM’s experiment with five cylinders created an engineering oddity that should never have left the drawing board. Constant vibration issues made the driving experience miserable. Multiple oil leaks turned owners’ driveways into environmental hazards. The unusual design made finding qualified mechanics nearly impossible.

5. Ram 3 L EcoDiesel V6

Ram’s Italian-sourced diesel engine brought European problems to American trucks. EGR system failures and turbocharger issues became the norm rather than the exception. The emissions control system seemed designed to fail, creating endless check engine lights. Repair costs often exceeded the engine’s benefits.

4. Chevrolet 5.3 L V8

If engineers wanted to demonstrate how to ruin a V8 with technology, the 5.3L provided the perfect case study. Active Fuel Management turned oil consumption into a serious problem. Lifter failures became so common that aftermarket companies developed bypass kits. The complexity of the engine made repairs expensive and time-consuming.

3. Ford 6.4 L Powerstroke Diesel V8

Ford’s 6.4L Powerstroke embodied everything wrong with modern diesel emissions systems. The complicated dual turbo system seemed designed to fail expensively. Radiator problems often led to complete engine failure. Repair costs regularly exceeded $10,000, destroying resale values.

2. Ford 6 L Powerstroke Diesel V8

The 6.0L Powerstroke stands as one of Ford’s most catastrophic failures. Head gasket failures occurred with shocking regularity, while oil cooler problems destroyed engines. Injector failures became so common that owners expected rather than feared them. This engine single-handedly damaged Ford’s diesel reputation for years.

1. Ford 5.4 L Triton V8

The 5.4L Triton earned its place as the worst truck engine through spectacular design flaws. Spark plug ejection became so common that Ford dealers developed special tools just for this problem. Timing chain failures destroyed engines without warning. The distinctive ticking sound served as a countdown to expensive repairs or complete engine replacement.