That viral video of Boston Dynamics’ Atlas robot sticking a perfect roundoff back-handspring isn’t just another jaw-dropping demo. The fully electric humanoid’s gymnastics routine at CES 2026 represents something bigger: robots finally moving beyond impressive YouTube clips into actual industrial deployment. This progress in workplace safety technology demonstrates the practical applications of advanced robotics.

While you’ve probably seen countless robot fails on TikTok, Atlas demonstrates the kind of dynamic mobility that makes warehouse managers take notes instead of screenshots.

Built for Business, Not Breakdancing

Atlas combines Olympic-level agility with industrial durability through modular design and serious specs.

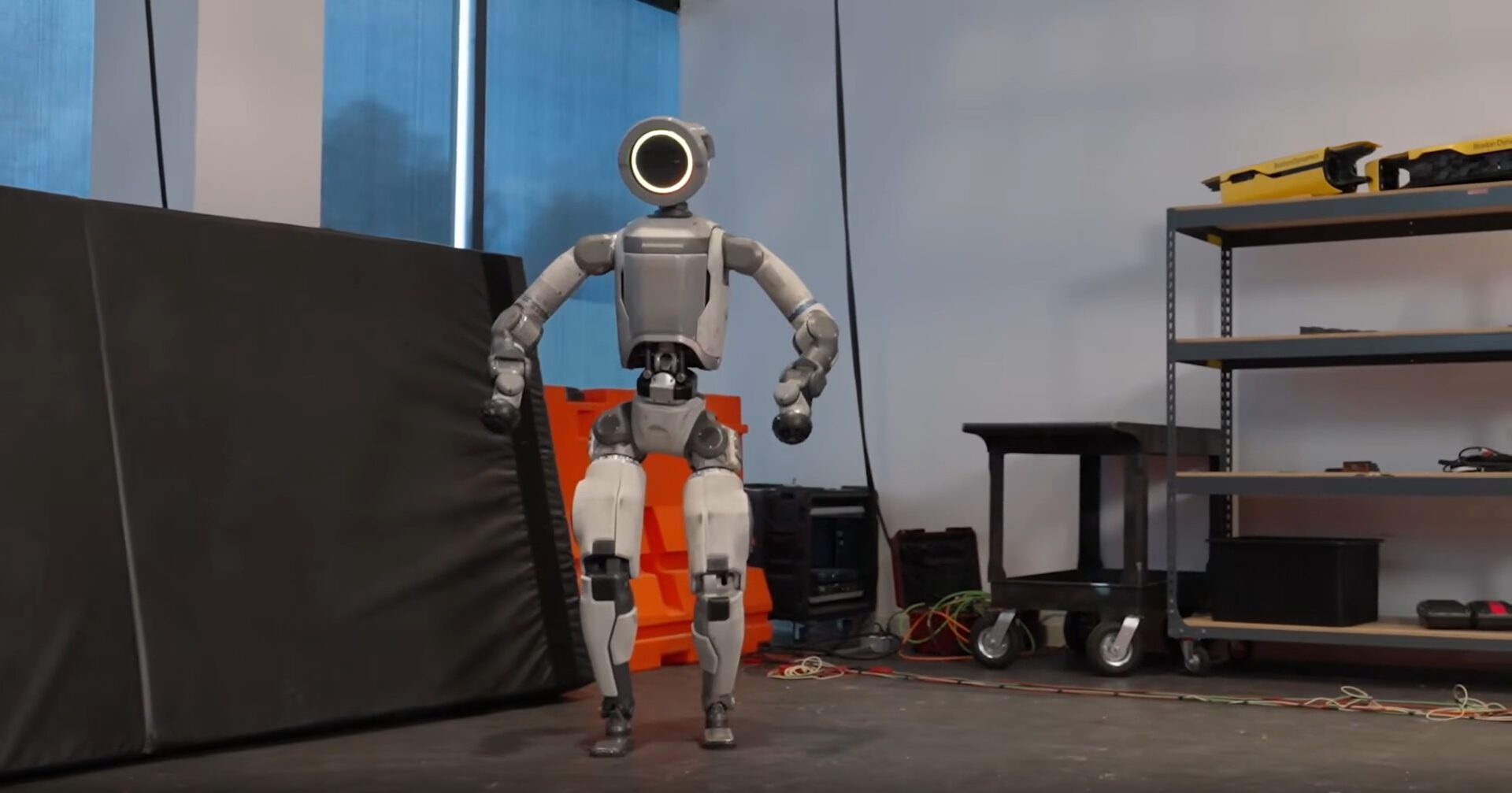

The new Atlas stands 1.8 meters tall, weighs roughly 85 kilograms, and lifts 110 pounds instantly—more than most humans manage safely. Its modular head packs 360-degree sensors with integrated compute, while fully rotational torso and head joints eliminate the awkward movements that plagued earlier humanoids.

Removable batteries provide four hours of runtime with IP67 weatherproofing, meaning this robot works through conditions that would sideline human workers.

Boston Dynamics ditched hydraulics for all-electric actuators, creating a platform that doesn’t leak fluid or require constant maintenance. The 28-56 degrees of freedom translate to human-like manipulation without human limitations—no coffee breaks, no sick days, no workers’ compensation claims. This level of robotic automation represents a significant advance from consumer applications.

Athletic Intelligence Meets Assembly Lines

Hyundai’s influence shapes Atlas for 2026 production as “athletic intelligence” enables complex industrial tasks.

“We’ve built this amazing athletic intelligence that helps our robots move through the world in incredible ways,” according to Boston Dynamics representatives at CES. That intelligence isn’t about impressing crowds—it’s about navigating cluttered warehouses, handling irregular objects, and adapting to unexpected obstacles without programming updates.

The 2026 production timeline has all deployment slots committed, with parent company Hyundai’s manufacturing expertise steering development toward practical applications. Fleet deployment through Orbit software lets multiple Atlas units share learned behaviors, building institutional knowledge faster than training human workers.

Boston Dynamics emphasizes coexistence over replacement, but when robots work 24/7 without fatigue, that distinction might feel academic to displaced workers. The real test isn’t whether Atlas can backflip—it’s whether companies can integrate humanoid workers while addressing legitimate economic concerns about automation’s impact on manufacturing jobs.