Traditional welding requires months of training and thousands in equipment, but the xTool MetalFab promises pro results from your first power-up. This modular system raised $1.7 million on Kickstarter by combining a handheld fiber laser welder with a precision CNC cutter base—think Swiss Army knife meets industrial fabrication.

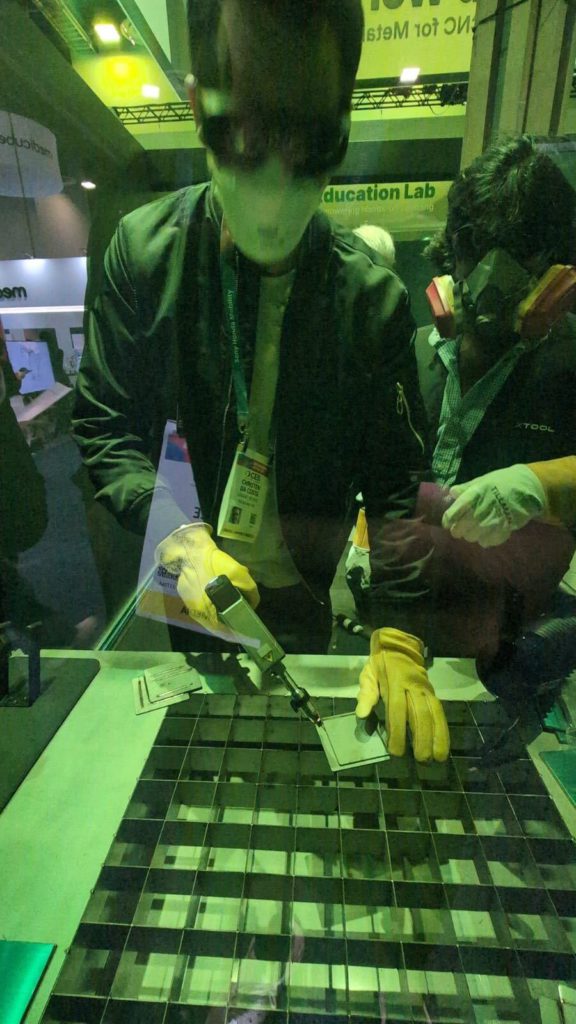

MetalFab tackles the maker community’s biggest frustration: accessing professional metalworking without the professional price tag or learning curve. I got to use it at CES 2026.

Industrial Power in Garage-Friendly Package

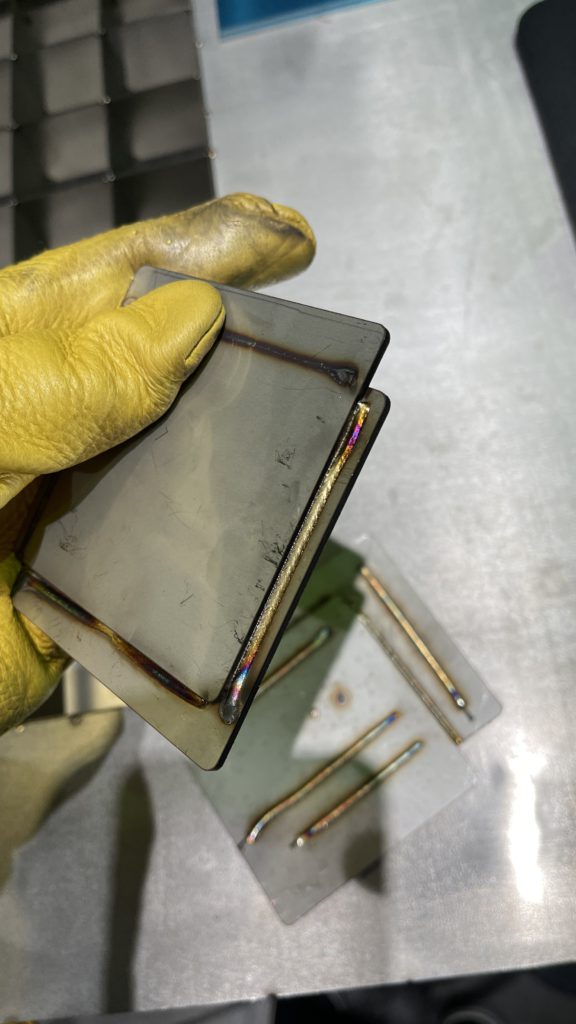

Modular design switches from cutting to welding in seconds, handling everything from titanium to aluminum.

The system’s core innovation lies in its modularity. The fiber laser welder detaches from its CNC base for handheld operation, letting users tackle on-site repairs or intricate assemblies. Available in 800W and 1200W variants, it cuts through 10mm carbon steel at 400mm/s—faster than most industrial setups found in traditional fab shops.

The 610x610mm cutting bed extends infinitely via FlexiTrack™ pass-through technology, while VibeFreeCut™ reduces the shake that typically ruins precision work. AI-driven nesting software achieves 98.7% material utilization, turning expensive metal sheets into minimal waste.

Learning Curve Meets TikTok Generation

XCS software promises “zero experience” results through 108+ presets and dual-camera guidance.

xTool claims their XCS AI software eliminates the traditional welding apprenticeship. Dual cameras—16MP panoramic plus macro detail—guide beginners through complex joints while 108+ material presets handle the technical variables automatically. The 8-inch touchscreen interface resembles smartphone operation more than industrial machinery.

That “zero experience” marketing deserves skepticism. While the software might prevent catastrophic failures, understanding metallurgy and joint design still matters. Think of it as advanced training wheels rather than autopilot.

Reality Check on Revolutionary Claims

It costs $18k for complete systems.

Kickstarter early birds secured systems for $4,000-$6,500, but retail pricing climbs to $18,000 for the 1200W combo. That’s still dramatically cheaper than comparable industrial equipment, but represents serious garage workshop investment.

Class 4 laser safety requires protective equipment and proper ventilation—this isn’t plug-and-play like xTool’s wood cutters. The underwater welding capability sounds impressive until most hobbyists lack the infrastructure.

The MetalFab democratizes metal fabrication the same way 3D printers transformed prototyping. Whether that justifies the investment depends on project ambitions and tolerance for early-adopter risk.