Your AC bill hits harder each summer while outside temperatures keep climbing. Traditional refrigeration technology traps us in a brutal cycle—more heat drives more cooling demand, burning more energy, creating more emissions. Enter magnetocaloric cooling, the first serious challenge to vapor compression systems in nearly a century. This tech slashes energy use by up to 30% while ditching harmful refrigerants entirely. Ready to see how magnets might save your wallet and the planet?

7. Stacking Small Changes into Big Results

Imagine trying to cool your house with single ice cubes. That’s the challenge each magnetocaloric material faces with tiny temperature shifts. Engineers stack these effects through active magnetic regeneration, layering multiple cooling stages for substantial temperature drops.

Magnotherm tests systems for thousands of hours, hunting microscopic inefficiencies in complex thermodynamic processes. Finding optimal regeneration cycles requires precision engineering, but the payoff delivers cooling power that rivals traditional systems without environmental baggage.

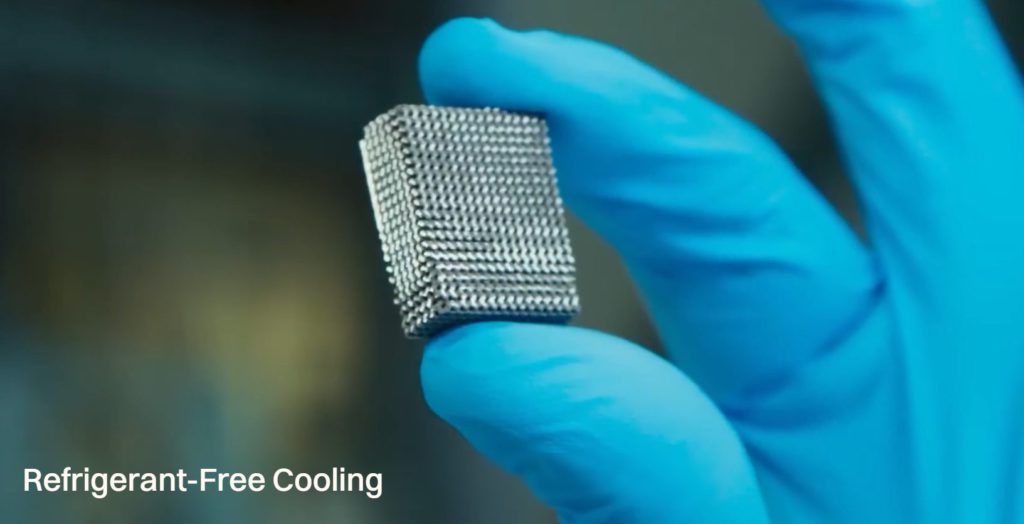

6. The Material Science Breakthrough

Gadolinium dominated early magnetocaloric systems as a rare earth metal that was more expensive than premium coffee beans. Magnotherm solved this roadblock with iron-based alloys containing lanthanum and silicon, manufactured through advanced techniques, creating Swiss cheese-like structures.

These interconnected channels maximize heat transfer efficiency like thermal superhighways. The breakthrough makes magnetic cooling economically viable rather than just scientifically impressive, opening doors for mass production and consumer adoption.

5. The Price Tag Reality Check

Between $7,573 and $18,645, magnetic refrigerators cost significantly more than conventional models right now. However, energy savings help users recover investments within three to five years, especially as utility rates climb and environmental regulations tighten.

Specialized applications like medical refrigeration and laboratory equipment already justify premium pricing. Precision temperature control and environmental benefits make magnetic cooling attractive for critical applications where reliability trumps initial cost considerations.

4. Numbers That Actually Matter

Thirty percent better efficiency separates magnetic refrigeration from conventional systems, though real-world performance varies by prototype maturity. Current Magnotherm models outperform many traditional units while completely eliminating environmentally harmful refrigerants.

Early prototypes started with modest performance, but each iteration improves dramatically. Laboratory conditions show impressive gains, though commercial deployment will determine actual efficiency in everyday applications across different climates and usage patterns.

3. The Magnetic Magic Trick

Atomic-level choreography makes conventional compressors look primitive in magnetocaloric cooling systems. Specific metals tighten their structure when exposed to magnetic fields, similar to concert crowds squeezing together for the headliner, releasing heat during this process.

Remove that magnetic field and atoms spread back out, absorbing heat from surrounding areas. This isn’t lab theory anymore. Real prototypes are replacing mechanical compressors with magnetic fields, eliminating moving parts that break down and refrigerants that harm the environment.

2. Power Play: Scaling Up

Four hundred Watts of cooling power defines current system capabilities. This works for compact refrigerators but falls short of the 600-1000 Watts needed for broader applications. Magnotherm has built larger prototypes reaching 2000 Watts using 50-kilogram magnets.

These represent stepping stones toward systems capable of cooling entire homes or commercial spaces, proving magnetic technology can scale beyond niche applications into mainstream cooling markets.

1. Magnotherm: Turning Physics into Fridges

Rotating magnets and specialized metal blocks form the foundation of Magnotherm’s magnetocaloric refrigeration systems. Water flows through closed loops, picking up heat from magnetized metals before getting chilled during demagnetization cycles.

No compressor grinding away in your backyard. No refrigerant gases escaping into the atmosphere. Their approach ditches 1920s technology for something that belongs in this century, delivering cooling through pure physics rather than brute mechanical force.