How does it perform?

The Creality Falcon A1 Pro delivers strong performance, with its 20W blue diode laser capable of cutting through 9mm cedar in a single pass, while the optional 2W IR module expands material compatibility to metals and ceramics. It boasts impressive engraving speeds of up to 600 mm/s, outperforming many rivals in its class. The autofocus system achieves a precision of ±0.012 inches (±0.3mm) in just 3 seconds, though consistent camera calibration is necessary for accurate placement.

What’s it do best?

The Falcon A1 Pro excels in versatility and user accessibility. It’s ideal for small business applications, offering tool-free laser head swapping and compatibility with over 350 materials to support diverse craft and custom production. For beginners, its fully enclosed Class 1 design means you can use it safely without goggles, though we still recommend getting a pair if you plan on using some of the calibration methods that involve opening the enclosure. The laser runs at a lower power, but it never hurts to be careful! Additionally, the built-in 8MP camera and mobile app provide convenient remote monitoring and design preview capabilities.

Laser Performance

Optical Power Output

Laser power determines cutting capability and material compatibility across different thicknesses and densities.

The blue diode module delivers 20W measured output, while the optional IR module provides 2W measured output. Customer testing confirms the 20W module efficiently cuts 9mm cedar in single passes, where 10W systems typically require multiple passes.

However, making these cuts will require adjustments to speed to produce clean cuts without excess overburn. You have a lot of control over power output, and that means you’re just as likely to burn material or create shallow cuts if you don’t spend the time dialing everything in.

Power Stability

Consistent power delivery ensures uniform cut quality and repeatable results across extended operations.

The system maintains stable operation, with reviews indicating reliable performance during batch processing without significant thermal drift. This consistency is crucial for uniform output over long jobs. We ran several particularly long jobs, and the consistency of the engraving was excellent.

Precision & Accuracy

Positioning Accuracy

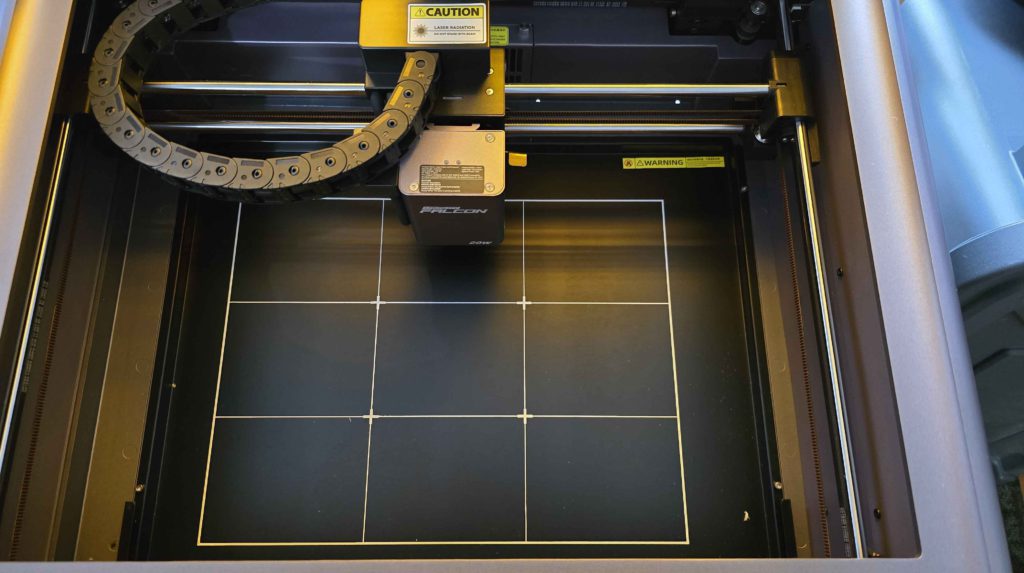

Precise positioning enables detailed work and multi-layer projects requiring tight tolerances.

The autofocus system provides a precision of ±0.012 inches (±0.3mm), which can create very fine details and cuts. That said, customer reviews note that camera calibration can be difficult and may require frequent manual adjustment for optimal placement. In our experience, initial calibration took some time, but once things were dialed in, we didn’t have to do much fiddling.

Repeatability

Consistent results across batch operations are crucial for efficient production. The Falcon A1 Pro demonstrates high repeatability, delivering consistent dimensional accuracy in repeated cuts and engravings, which is essential for batch production workflows.

Beam Spot Size

Smaller spot sizes enable finer detail and cleaner edges in both engraving and cutting applications. While a specific beam spot size in micrometers hasn’t been tested, test results show crisp edges on 3mm basswood with minimal charring when properly focused. This indicates a well-focused beam.

Our own experience supports this, though getting a good cut on one pass requires careful adjustment of the speed at which the laser moves to ensure you cut through the basswood in one go (or multiple passes, which we preferred since it helped reduce overburn).

Speed & Throughput

Maximum Engraving Speed

Processing speed directly impacts productivity for both hobbyist and commercial applications.

The Creality Falcon A1 Pro achieves an impressive maximum engraving speed of 600 mm/s, notably faster than many competitors in its class.

Processing Time per Unit Area

Real-world throughput testing demonstrates practical productivity capabilities. Detailed engravings of complex patterns on smaller areas can take around 20 minutes, while simpler cuts can be completed in 2-4 minutes. Customer feedback confirms the machine’s efficient batch processing capabilities for small business applications.

Simple cuts and designs take a few minutes, but anything complex with lots of details and shading rapidly balloons the time you’ll be waiting for a cut to finish, though this is expected and not unusual.

Safety & Compliance

Interlocks Functionality

Comprehensive safety systems protect operators and prevent accidental exposure to laser radiation. The machine features magnetic switches on both access doors, an accessible emergency stop button, and a dual flame detection system with automatic shutdown. Customer testing confirms these interlocks function properly, pausing laser operation immediately when doors are opened. We tested this ourselves and confirmed it does indeed work.

Emission Containment

The fully enclosed design is critical for containing laser emissions. Multiple reviews confirm that the enclosure effectively contains laser light, eliminating the need for safety goggles during normal operation. This also helps with fume extraction, though you’ll still notice a smell as material burns, and good ventilation is an absolute must if you’re setting this up in a smaller space.

User Experience & Ergonomics

Ease of Operation

User-friendly features and interfaces determine adoption success and daily productivity.

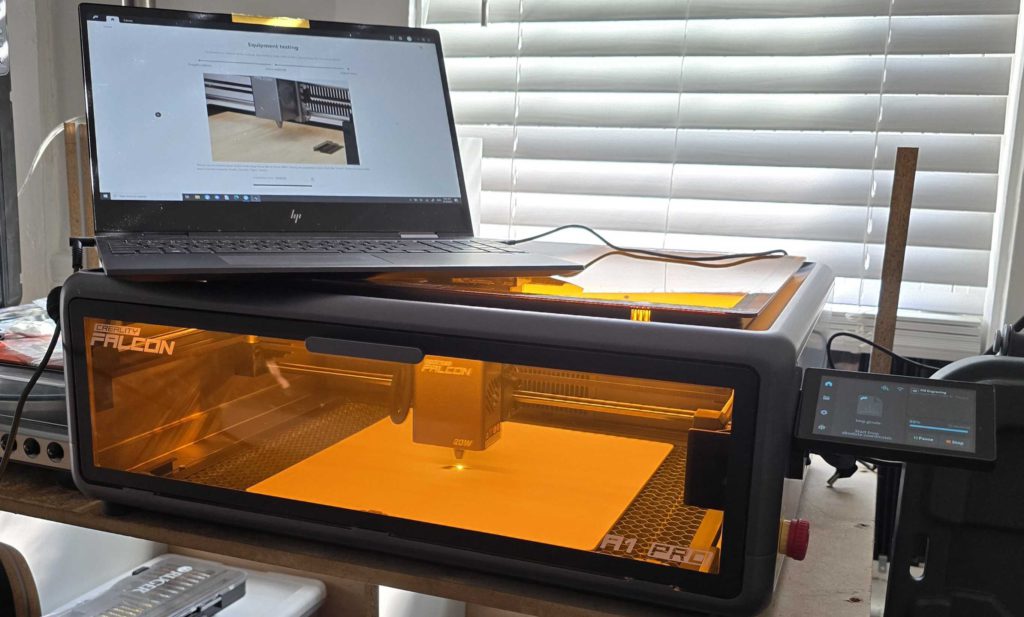

The typical setup time from unboxing is 20-30 minutes, with a reported average of 25 minutes. Reviews consistently praise the straightforward setup process and intuitive touchscreen interface for basic operations, making it beginner-friendly. Our own setup process took around 30 minutes and was very straightforward.

Access & Maintenance

Practical design considerations affect long-term usability and maintenance requirements in a positive way.

The machine features both top and front doors for easy material loading and access. Laser head swapping is tool-free and can be done in under 10 seconds, simplifying maintenance and module changes. The first time we removed the module, it took us longer than 10 seconds, but that was more from unfamiliarity. Replacing the module was so simple we thought we’d made a mistake! We hadn’t; we were just paranoid.

Build Quality & Aesthetics

Construction Quality

The Creality Falcon A1 Pro is highly praised for its premium, solid, and safe build. Reviews consistently describe it as well-built with excellent design, fantastic fit and finish, and robust hardware. We wholeheartedly agree, though we don’t recommend being rough with the machine’s moving parts.

Visual Design

The visual design receives positive feedback, characterized by a space gray metal finish with orange accents. The aesthetic is an excellent blend of professional and appealing, creating a very eye-catching machine that’ll stick out even among clutter.