If you’re looking for the best digital camera with WiFi, you’ll want a model with enhanced connectivity and ease of use. While all WiFi digital cameras allow you to connect to any available network, many models also let you set a destination for your transferred files, whether it’s via email, uploaded to your favorite social media platform, or saved to a file on your computer. Many brands also offer a companion app that lets you seamlessly manage file-sharing or other built-in functions.

These features are great for sharing photos while you’re on vacation. Transferring files directly from the camera over a wireless network connection is also convenient for photojournalists or bloggers. Keep reading our best digital camera with WiFi buying guide to learn more about these amazing devices.

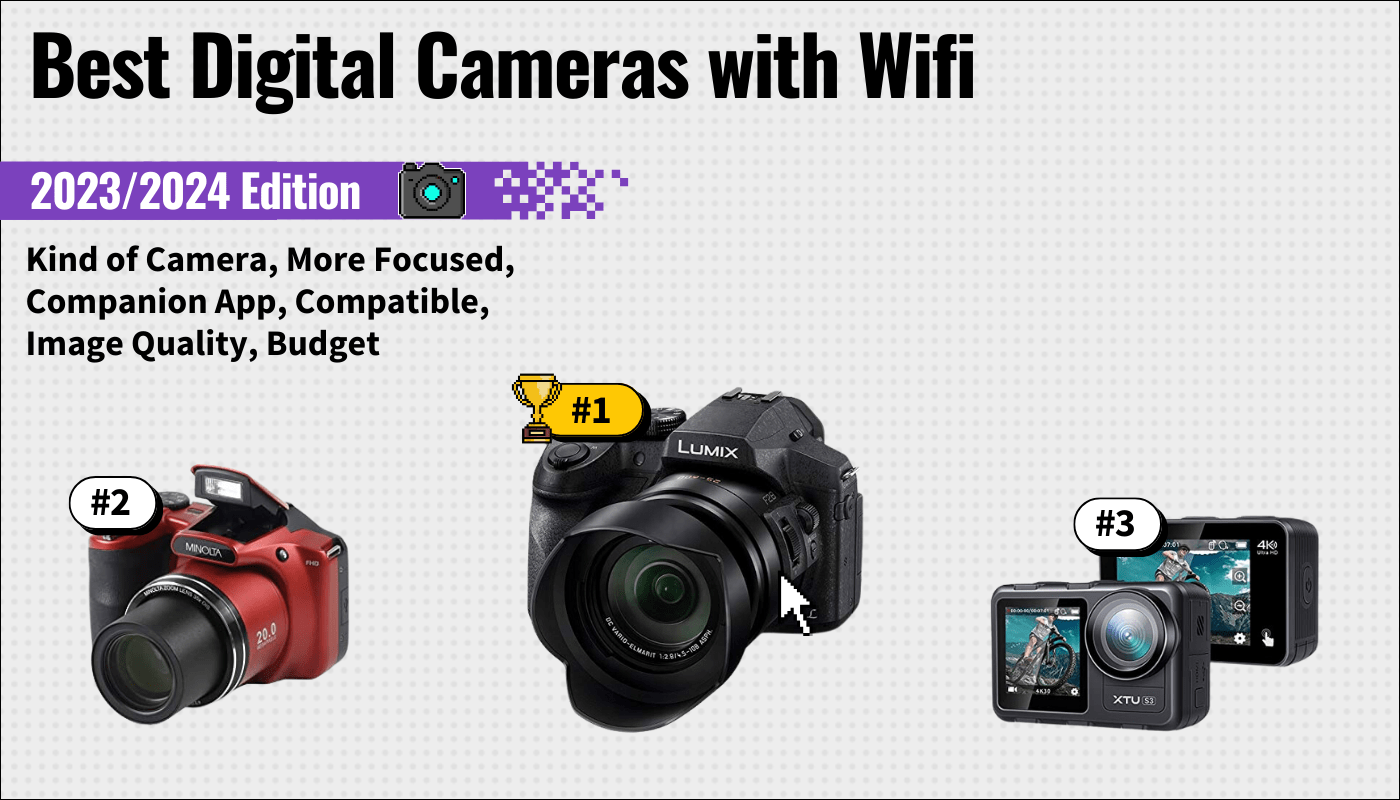

Top Digital Cameras With Wi-Fi

#1 Panasonic LUMIX FZ300 12.1MP Digital Camera

Award: TOP PICK

WHY WE LIKE IT: This camera records UHD videos, which will suit people who want to make documentaries and vlogs. The camera captures clear images from far and is rugged for durability.

- Superb video recording prowess

- Rugged splashproof and dustproof design

- 24x optical zoom lens

- Low-resolution photos

The Panasonic LUMIX FZ300 12.1MP digital camera is an excellent choice for people who want to capture high-quality videos and photos. This camera features an SLR-style body, providing intuitive operation. The camera has a MOS sensor that produces colorful, natural photographs. This camera comes with a Leica DC Vario Elmarit lens with up to 24x optical zoom, capturing clear images from far. Built-in Wi-Fi facilitates transferring media files easily. However, the photos produced by this camera are relatively low resolution.

A full zoom range F2.8 aperture enables shooting clear images even in low light conditions. This Panasonic LUMIX FZ300 12.1MP digital camera has a rugged construction, which stands up to regular use and frequent travel. The camera features a five-axis hybrid optical image stabilizer to prevent image blur. It records videos in resolutions up to 4K, so it’s a good pick for amateur videographers. This camera is splash-proof and dustproof, making it a good choice for people who work in extreme environments.

#2 Minolta MN35Z 20MP Digital Camera

Award: HONORABLE MENTION

WHY WE LIKE IT: This camera produces high-resolution images and videos, so it’s a good choice for semi-professional users. It has a high-quality wide-angle lens with impressive zooming abilities.

- Impressive photo quality

- 35x optical zoom

- Stylish design

- Poor battery

The Minolta MN35Z 20MP digital camera features a brilliant design that will stand out. This camera has image stabilization tech to reduce the likelihood of blurred photos. It has several scene modes, so it can be used in a wide variety of settings. Its wide-angle lens is perfect for portraits and group photos. This camera has a 20-megapixel sensor, capturing very detailed and sharp photographs. However, the battery life of this device is relatively low.

This Minolta MN35Z 20MP digital camera has built-in Wi-Fi and works with the Minolta ProShot app for transferring photos and videos. A 3.0-inch 460K LCD offers impressively detailed photo previews. Additionally, the camera captures Full HD videos and has several rotary dials and dedicated buttons for ease of use. This camera features an autofocus function to aid in taking shots. Featuring up to 35x optical zoom, this device is suitable for recording and shooting objects from afar.

#3 XTU S3 20MP Digital Camera

Award: BEST FOR PROFESSIONALS

WHY WE LIKE IT: Advanced features such as image stabilization, 360-degree recording, and a broad framing lens enable using this great vlogging camera for YouTube and documentary making. The water-resistant construction enables filming in water.

- Ultra HD video recording

- Rugged waterproof construction

- Incredible image stabilization system

- So-so 1080p videos

The XTU S3 20MP digital camera is an action model marketed to vloggers. Documentary makers will be pleased with this device’s 4K videos at 30 fps recording qualities. It comes with a 1350 mAh rechargeable lithium-ion battery which records for up to 2 hours on a single charge. This camera has a 160-degree wide-angle lens that offers a wide field of view. It records 360-degree videos, so it’s a good choice for professionals. However, the video quality when recording at 1080p is mediocre.

This XTU S3 20MP digital camera has dual screens, with a front-facing screen for selfies and vlogging. The camera has a built-in Electronic Image Stabilizer that helps eliminate camera shake for blur-free photography. It’s waterproof up to a depth of 16 feet, supporting recording while swimming and it also comes with an external housing that makes the device waterproof to a depth of 130 feet. This camera is Wi-Fi enabled and works with the XTU Go app for content sharing.

#4 Canon PowerShot ELPH 360 20.2MP Digital Camera

Award: BEST FOR LOW-LIGHT PHOTOGRAPHY

WHY WE LIKE IT: Equipped with Canon’s HS System, this camera offers excellent low-light performance and it will appeal to photographers who work in dark conditions. It produces sharp, detailed photos that will endear it to professional users.

- Outstanding performance in low light

- Compact design

- 12x optical zoom

- Average battery life

The Canon PowerShot ELPH 360 20.2MP digital camera impresses with its compact construction. The camera has built-in Wi-Fi and NFC, enabling users to share images and videos via a mobile app. It also works with the Camera Connect App for remote shooting. It has a 20.2-megapixel CMOS sensor and a DIGIC 4+ image processor, producing incredibly sharp images. However, the battery life of this model is not suitable for whole-day projects.

This Canon PowerShot ELPH 360 20.2MP digital camera also records videos at 1080p. A large 3.0-inch LCD supports hassle-free framing, and it has an optical image stabilizer system that counters camera shake. With a powerful lens that zooms up to 12x, this device captures photos from a distance. This digital camera uses Canon’s HS System, enhancing photos taken in low-light conditions. It comes with a rechargeable lithium-ion battery for hassle-free operation on the go.

#5 Vjianger YL04 48MP Digital Camera

Award: BEST FOR LIVE STREAMING

WHY WE LIKE IT: The camera captures super-detailed photographs that are suitable for framing. The two included lenses support using this device as a webcam for live streaming

- Outstanding photo quality

- 4K UHD video recording

- Can be used as webcam

- Motion blur

- Poor zoom function

Videographers will be pleased with the Vjianger YL04 48MP digital camera. This device captures 4K UHD videos at 30fps. It has a 48-megapixel photo sensor, capturing incredibly sharp and vibrant photos. Equipped with wide-angle and macro lenses, this camera captures both up-close portraits and wide group photos perfectly. It can be used as a webcam by connecting via a USB interface. However, although this device has a digital zoom function of up to 16x, the resulting images appear dark and pixilated.

This Vjianger YL04 48MP digital camera features a 3.5mm connector for attaching external mics for professional video recording. Built-in Wi-Fi allows transferring photo and video files easily to other devices. It has a compact build making it a nice digital camera for travel that will appeal to people who travel regularly. A rotating 180-degree LCD display on this model enables framing and monitoring settings easily. This camera has a retro design that brings classic vibes to the home. It comes with a 32GB TF card for storage.

#6 LuckyCam R9 48MP Digital Camera

Award: BEST FOR REMOTE OPERATION

WHY WE LIKE IT: This camera works with a mobile app to share photos and supports remote operation via the app. We love its 48MP sensor and 4K video recording capabilities.

- Impressive photo and video quality

- Wide-angle lens

- Remote operation via a mobile app

- Poor zoom function

The LuckyCam R9 48MP digital camera features advanced functions that will appeal to professional photographers and videographers. With a 48-megapixel CMOS sensor, this device captures colorful, vibrant photographs. It records videos at resolutions of up to 4K at 30 fps. The camera has a 3.0 TFT LCD flip LCD that offers accurate previews and enables changing settings easily. However, the 16x digital zoom function on this device produces poor-quality images.

This camera has built-in Wi-Fi, enabling users to transfer photos and videos easily. It works with the XDV PRO mobile app to share media and supports remote operation via the app. The LuckyCam R9 48MP digital camera has a built-in flash for enhancing photos and videos in low-light conditions. It comes with a 32GB memory card for accommodating media. With multiple shooting modes and a continuous shooting function, this device offers flexibility. We love its retro design that offers a touch of mid-century charm.

Beginner’s Guide to Digital Cameras with WiFi

What are Digital Cameras with WiFi?

A WiFi-enabled digital camera is simply a digital camera that can connect to a network, allowing you to transfer photos or videos directly from your camera to another destination. This enhanced connectivity is becoming increasingly standard as smartphones continue to replace point-and-shoot cameras. Additionally, if you’re looking for a device that can deliver a high-quality image than what your phone can provide, with a wider price range and touch screen capabilities, WiFi-enabled digital cameras offer an ideal option.

Across all categories (compact, DSLR, and mirrorless), you can find cameras that offer WiFi support. In most cases, this means that, at a minimum, you can wirelessly transfer images directly to your smartphone or another connected device like a laptop or tablet. But many WiFi-enabled cameras also support social media connectivity. This means you can post directly to a selection of social media platforms without the added steps of uploading your pictures to a separate device and then posting to your accounts.

Many WiFi-supported cameras also come with proprietary apps that allow you to control file-sharing or social media posting. But these apps can also serve as camera remotes, allowing you to work technically hands-free or even to fine-tune your camera settings remotely.

If you’re looking for a camera that offers these features, be sure to look out for units with additional spare batteries and rear screens to enhance your flexibility and visibility while taking pictures, all at a reasonable price.

Digital Cameras with WiFi vs. Other Cameras

The biggest difference between a WiFi-enabled camera and other cameras is the presence or absence of connectivity. With cameras that don’t feature WiFi functionality, you’re not able to wirelessly transfer content from your camera to your devices. Instead, you’ll either need to use a USB cable to create a physical connection or remove your camera’s SD or micro SD card and place it in a card reader connected to your computer or other devices.

Aside from connectivity, standard digital cameras aren’t that much different than those with WiFi. As we mentioned earlier, You can find WiFi support across all the core camera niches — and of course, with smartphones, if you want to include them in the compact category. Similarly, key selling points, like optical zoom, image quality, or camera accessories compatibility, are going to be equally important for WiFi-enabled cameras.

How Digital Cameras with WiFi Work

In terms of taking pictures or video capture, a digital camera with WiFi functionality operates exactly like its WiFi-free counterpart. But the WiFi component can vary slightly as every camera brand has a specific set of steps to access and manage WiFi controls and functions.

In some cases, your camera is equipped with WiFi connectivity and Bluetooth support to create a dedicated connection with other portable tech devices like tablets and smartphones. Manufacturers often create proprietary apps that you must use to establish the WiFi connection and manage operations like transferring images or uploading content to social media platforms. Although, this is different from manual cameras, and if you want to learn more, check out our guide to a film camera vs digital.

Note that not all WiFi-enabled digital cameras support social media. But those that do can be incredibly convenient for more social media savvy camera users. For example, modern instant cameras such as the Polaroid Now+ feature social media support that allows you to post directly to Instagram or Facebook via their app.

Why You Should Buy a Digital Camera with WiFi

There are plenty of valid reasons why a digital camera with WiFi support should be on your radar. Even if you’re just understanding how to use a digital camera, having multiple connectivity options is ideal. A WiFi-enabled camera is incredibly useful for travel photographers, bloggers, and social media influencers. If your current camera lacks Wi-Fi connectivity, upgrading to a model that has it is well worth it, especially if you’re constantly taking photos or simply dislike dealing with USB cables.

Are Digital Cameras with WiFi Worth Buying?

- You’re Running Out of Storage Space: Serious shutterbugs know that there’s nothing more frightening than running out of storage space on your camera. WiFi support allows you to instantly back up your photos to a device or the cloud, allowing you to get back to capturing the perfect shots.

- You’re Cutting the Cord: If you despise dealing with wired connections, there’s a lot to love about WiFi-friendly cameras. The biggest benefit is that you can transfer files without getting caught up in cords and wires.

- You Like the Idea of Capturing Remote Shots: Many camera manufacturers have created proprietary apps for their WiFi-enabled cameras. Not only do these apps help you manage file transfers, but in many cases can also serve as a remote control for live shots and even streaming.

Why Digital Cameras with WiFi May Not Be for You

- You Don’t Take That Many Pictures: If you only use your camera occasionally, you might find that the biggest selling point about WiFi-enabled digital cameras isn’t that compelling.

- You Use Your Smartphone: Technically speaking, your smartphone is a WiFi-enabled digital camera. But for this buying guide, let’s just say that if you rely on your mobile phone to snap pictures, a true WiFi-enabled camera might be redundant.

- You’re Transferring Large Files: To be clear, most digital cameras with WiFi functionality can establish fairly stable connections with other devices. But, if you’re trying to move large files between your camera and a device, a wired connection is always going to be preferable because it’s faster. However, digital cameras with WiFi do come with USB cables too.

How Long Will Digital Cameras with WiFi Last?

As with other digital cameras, the answer to this question will depend on the type of camera you have, along with user behavior. People who own DSLR or mirrorless cameras should consider the shutter actuation or shutter count — a figure that refers to how many images your camera’s shutter can capture before that component begins to fail.

Shutter count matters more for DSLR cameras because these bodies have mechanical shutters. In comparison, mirrorless cameras also include a digital shutter, which can extend your shutter count significantly. Shutter count varies widely across brands and even between the models a brand offers. On the low end, you can find cameras that can only capture roughly 50,000 pictures, while other models go beyond 500,000.

With point-and-shoot or compact cameras (we’ll include smartphones in this group), shutter count isn’t an applicable metric. In most cases, these cameras are fairly durable and can last many years before you find that you need to replace them. With smartphones, it’s more likely that you’ll upgrade to a new phone before you wear out the camera function.

On the other hand, for those seeking a more advanced camera, such as a DSLR or mirrorless system with a full-frame sensor and manual modes, shutter count can be an important factor when choosing between such models. Additionally, if you’re selecting a lens to pair with your camera body, it’s important to consider the selection of lenses available. Bright sunlight, focal range, and maximum aperture are all important factors to consider when selecting a lens.

But regardless of the type of camera or camera-like device you own, user behavior will impact longevity. While DSLR and mirrorless cameras are fairly durable and can often be used in rugged conditions, you will shorten your camera’s lifespan by exposing it to the elements, abusing the camera body, or frequently allowing it to overheat.

Similarly, compact cameras are also susceptible to rough treatment. And, of course, nothing ruins a smartphone better than repeatedly dropping it and cracking the screen. In some cases, the screen can become so damaged that the phone isn’t even functional anymore.

How to Choose the Best Digital Cameras with WiFi

While WiFi support is important, most likely, this isn’t the only reason you’re thinking of buying a camera. You’ll want to pay attention to other criteria that impact your camera’s primary function, such as image quality, shutter count, and of course, ease of use.

Best Digital Cameras with WiFi Key Factors to Consider

1. What kind of camera do you want?

WiFi support isn’t exclusive to one specific camera category. You can get a DSLR, mirrorless, or compact camera that offers WiFi functionality. Note that there’s another category known as action cameras which also support WiFi connectivity. The most well-known in this niche is the GoPro. Think about your photography goals, and find a camera that’s compatible with those aspirations.

2. Are you more focused on photos or video?

When it comes to the photos versus video debate, not all cameras are created equal. While pretty much every camera can take pictures, some offer better video quality — especially if you’re attempting to live stream. If you’re focused on video, consider whether the camera supports true HD capture of at least 1080p. But in many cases, you can even find video features that support 4K, including compact cameras.

3. Do you want a companion app?

Companion apps tend to be a standard feature for WiFi-enabled digital cameras. But not all apps are created equal. Some apps are only designed to manage the WiFi connection or to support photo sharing between devices. In contrast, other brands have developed apps that can act as remotes for your camera or support social media connectivity. Think about what features are most important to you and prioritize that as you shop.

4. Is it compatible with accessories?

Camera accessories can vary widely, ranging from typically universal items like camera straps to options like camera lenses traditionally reserved for DSLR and mirrorless cameras. Knowing if you want to swap out lenses or add options like an external microphone can help narrow your search.

5. How is the image quality?

As a general guide, DSLR and mirrorless cameras are traditionally known for capturing excellent image quality and color clarity, thanks to having larger image sensors. But these days, it’s possible to find compact cameras — and yes, even smartphones — that can create stunning images. How’s this possible? Likely, it’s the millions of pixels used in the device.

With compact cameras, a typical rule of thumb is to look for more megapixels as a higher number of megapixels usually translates into better image quality. For the best DSLR camera or mirrorless camera, you’ll also want to consider settings such as aperture and full manual controls. While you can sometimes find aperture and manual support with compact cameras, it’s not always common as these models tend to have basic controls.

6. What’s your budget?

WiFi-supported cameras are still a feature and not a standard option for digital cameras. With that in mind, know that you’ll most likely spend more than you would on a budget compact camera. Still, camera costs can vary with DSLR and mirrorless versions offering models ranging from median to incredibly expensive. However, there are quite a few compact cameras with WiFi support at an affordable price.

Owning a Digital Camera with Wi-Fi

Owning a camera with Wi-Fi offers significant convenience and flexibility in photography. It allows for easy transfer of images and videos to smartphones, tablets, or computers without needing cables. This feature is particularly useful for quickly sharing photos on social media or with clients.

Wi-Fi-enabled cameras often support remote shooting and camera control through a smartphone app, which is advantageous for capturing shots at difficult angles or for discreet photography. Additionally, the ability to back up photos wirelessly to cloud storage directly from the camera enhances the safety and accessibility of your photographic work.

Minimize Glare on a Digital Camera’s Display

Knowing how to minimize glare on a digital camera display is crucial for photographers. It ensures clear visibility of the screen in various lighting conditions, allowing for better composition and focus for capturing high-quality images.

Minimizing glare on a digital camera display involves several techniques.

- Position the camera or yourself to avoid direct light sources.

- Use a camera hood or an anti-glare screen protector.

- Adjust the camera’s display settings like brightness and contrast are effective methods.

Some cameras also come with viewfinders as an alternative to LCD screens, which can be helpful in bright conditions.

Features to Consider When Buying a DSLR Camera

The best DSLR cameras are known for their exceptional image quality, versatility, and manual controls, catering to both amateur and professional photographers. They offer features like high-resolution sensors, advanced autofocus systems, and robust construction, suitable for various photography genres.

These cameras provide creative control and flexibility, enabling users to adapt to different shooting conditions and preferences.

Maintaining a Digital Camera

Maintaining a digital camera is crucial for its longevity. Regular cleaning of the lens, shutter, and viewfinder using appropriate supplies is important to avoid damage and maintain photo quality. Additionally, troubleshooting common issues like power problems and blurry photos involves checking the battery, cleaning contacts, and updating the camera’s software.

Extended warranties might not be necessary, as most cameras are robust enough to last without needing warranty repairs, with even basic cameras having significant shutter lifespans.

Specification Sheets: